LOAD & UNLOAD TRAILERS IN 5 MINUTES

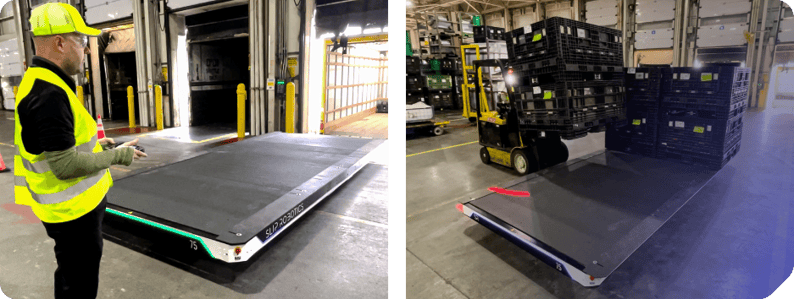

SlipBots slash trailer loading & unloading time from an average of 50 minutes to just 5 — eliminating delays, reducing risks, and delivering full value within your first week.

Trusted by Industry Leaders

Accelerate Your Dock

Cut trailer dwell time by 90%.

Slow trailer loading & unloading is one of the biggest bottlenecks in modern logistics—costing time, money, and throughput. Manual loading processes are inconsistent and slow, creating delays and safety risks at the dock.

SlipBots autonomously load & unload trailers in < 5 minutes, transforming your operation into a fast, predictable, and scalable system without requiring infrastructure changes.

Automation Built for Safety

Zero forklifts in the trailer.

SlipBots eliminate one of the most dangerous parts of warehouse work—forklift operations inside trailers. With fully autonomous entries and exits, freight moves in and out without putting people in confined or hazardous spaces.

By removing manual movement from the trailer, SlipBots create a safer, steadier environment on every shift—while helping you avoid the hidden costs of accidents, insurance claims, and compliance gaps.

Fast Track Your ROI

Zero Wi-Fi. Zero IT. Zero retrofits.

SlipBots are built for fast, frictionless deployment—no Wi-Fi connections, no IT integration, and no changes to your trailers or docks. They work with the systems and infrastructure you already have.

While most automation takes months to implement and optimize, SlipBots start delivering value in days. From first delivery to first ROI, most sites are fully operational and seeing measurable impact by the end of week one.

Frequently Asked Questions

What kind of freight can SlipBots handle, and what’s the payload capacity?

SlipBots can handle nearly any freight type—pallets, totes, bins, racks, loose items, and even non-stackable or hand-loaded freight. Each SlipBot has a payload capacity of 12,000 lbs, with three SlipBots per trailer for a total truckload capacity of 36,000 lbs. For heavier applications, the SlipHeavy model increases capacity to 20,000 lbs per bot—up to 60,000 lbs per truck. Payload is tracked in real time via an onboard scale, with readouts displayed on the controller and LED indicators on the bot for quick visibility.

How much room do I need on my dock?

SlipBots operate in the same space you already use to stage materials—no additional floor space required. In fact, their ability to rapidly load and unload can help free up valuable dock space by reducing dwell time. Equipped with omnidirectional wheels, SlipBots maneuver easily in tight areas, allowing for flexible placement and smooth operation in nearly any facility layout.

How long do SlipBots run, and how are they charged?

SlipBots are designed for continuous industrial use and can operate without plugging in. Each unit has two swappable lithium-ion batteries that trickle-charge the main internal battery throughout the day. Swapping takes less than 2 minutes and provides up to 10 hours of runtime.

The main battery can power a SlipBot for up to two full days of use and rarely needs direct charging. All SlipBots meet DOT safety standards and use lithium-ion batteries well below hazmat thresholds, so there are no special requirements for transport or handling.

Is it safe for SlipBots to operate around people and forklifts?

Yes. SlipBots are built with multiple onboard safety systems to navigate busy loading docks with precision. They use sensors, lidar, and vision systems to detect obstacles and people in real time—ensuring safe operation in shared environments. They’re designed to stop automatically if something enters their path and can operate seamlessly alongside your existing equipment and teams.

How long does it take to deploy SlipBots?

Most sites are up and running in less than a week. SlipBots require no changes to your docks, trailers, or infrastructure. Our team handles setup, training, and supervised operations—so your staff is confident, your process stays intact, and your operation sees value almost immediately.

What kind of training or change management is needed?

Training doesn’t stop after deployment. Slip supports your team from day one and every day after. We provide hands-on training during installation, then continue to support ongoing coaching, process optimization, and team onboarding for as long as you have SlipBots on-site. As your operation evolves, we help ensure your automation continues to deliver maximum value.

What does maintenance and support look like?

Our team monitors every SlipBot in the field and provides proactive support as part of your subscription. With remote diagnostics, on-site service, and regular updates, we keep your system running smoothly—so your team can stay focused on moving freight.

How much does a SlipBot system cost under your Robots-as-a-Service model?

SlipBots are offered through a monthly Robots-as-a-Service (RaaS) model that most customers treat as an operating expense. There’s no large upfront investment—just a flat monthly fee that covers the robots, support, updates, and ongoing maintenance. After a quick intro call, we’ll provide a tailored ROI analysis and cost estimate based on your operation’s specific needs.

How is Slip’s pricing model different from buying or leasing equipment?

Slip uses a Robots-as-a-Service (RaaS) model—offering SlipBots through a monthly subscription rather than a large upfront capital expense or a basic lease. Unlike traditional leasing, our model includes full support, maintenance, software updates, and hardware upgrades. You get continuous improvements and hands-on service without the burden of ownership.

Can you help us build the business case?

Absolutely. After your initial call, our team will work with you to build a detailed ROI analysis based on your dock volumes, labor costs, and trailer flow. We help quantify the time and cost savings, making it easy for your team to evaluate the opportunity and justify the investment internally.

Talk to Us About Your Dock

Seeing is believing — but even if you’re not ready for a demo, we’re here to talk. We offer free on-site SlipBot demonstrations to show just how fast, simple, and safe automated trailer loading can be. Whether you’re ready to schedule or just want to explore how it could work at your dock, our team is happy to connect.

Want A Free Onsite Demo?

- Schedule an intro call with our team.

- Discuss your project with our team.

- Our team will setup a time to bring a SlipBot to your dock.